Discover a Wide Range of Fibre Optic Tools and Termination Kits for Your Needs

By:Admin

Fibre optic technology has revolutionized the way we communicate and transfer data today. With its high-speed capabilities, low latency, and reliable signal strength, fibre optic cables are the preferred choice for telecommunications networks, data centres, and other high-bandwidth applications. However, to design, install, and maintain fibre optic cable networks, one needs specialized tools and equipment. In this blog, we will explore the various types of fibre optic tools and termination kits available at Anderson Corporation.

Fibre Optic Tools

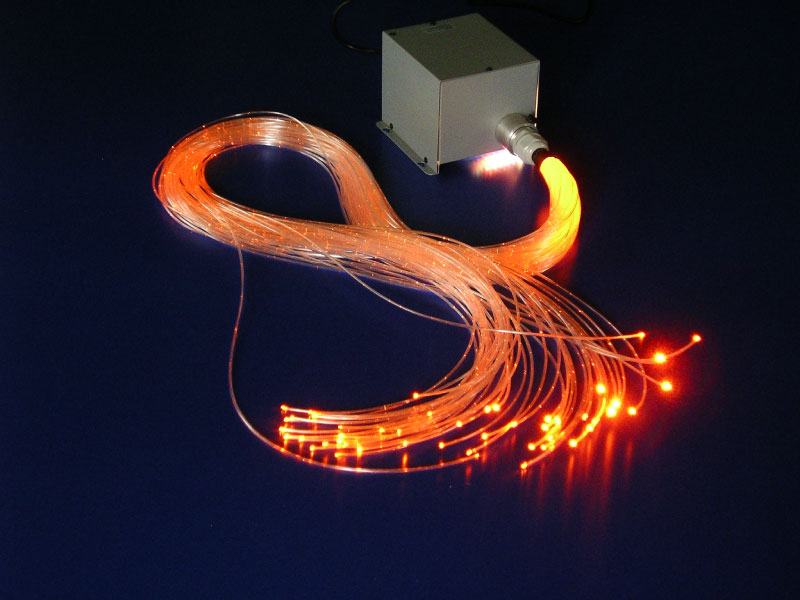

Fibre optic tools are specialized equipment designed to handle fibre optic cables and the installation process. Tools such as cable strippers, cleavers, fusion splicers, OTDR testers, and visual fault locators are some of the fibre optic tools essential for installing, maintaining and repairing fibre optic cables.

A fibre optic cable stripper is used to remove the insulation layer of a fibre optic cable without damaging the thin glass fibres inside. Cable cleavers are used to precisely cut the fibre optic cable, ensuring a clean break without splinters. Fusion splicers are used to splice or join two fibre optic cables together by melting the glass fibres and fusing them together. OTDR testers or Optical Time-Domain Reflectometers are used to detect and locate faults or weak points in the fibre optic network. Visual Fault Locators are small handheld devices that emit a visible laser light to locate breaks or faults in the fibre optic network.

Termination Kits

Fibre optic termination kits are a set of tools, connectors, and cables used to terminate or connect a fibre optic cable to a device or network. These kits are available in different types and sizes, depending on the specific project requirements.

At Anderson Corporation, we offer a range of fibre optic termination kits, such as pre-polished connectors, splice-on connectors, mechanical connectors, and field-installable connectors. Pre-polished connectors are factory polished connectors that require minimal on-site polishing. Splice-on connectors are used for quick and easy termination of fibre optic cables in the field. Mechanical connectors are user-friendly, cost-effective connectors that are easy to install without polishing. Field-installable connectors are convenient and easy to install connectors used in harsh environments, remote locations, or emergency situations.

Conclusion

As mentioned earlier, fibre optic technology is the future of telecommunications, and installing and maintaining fibre optic cables require specialized tools and equipment. Anderson Corporation offers a range of fibre optic tools and termination kits to ensure a smooth and successful fibre optic installation. Whether you are a network installer, contractor, or a data centre operator, we have the right tools and kits for your needs. Contact us today to learn more.

Company News & Blog

What is a Voltage Transformer and How Does It Work?

In today's modern world, the demand for electricity is rapidly increasing, and so the need for voltage transformers becomes more and more significant. Voltage transformers can be found in various types of electrical devices, ranging from the smallest appliance to the largest power grid systems. These transformers play a pivotal role in maintaining the stability and safety of our electrical supply.Voltage transformers are designed to convert high voltage electricity into lower voltage electricity, or vice versa, depending on the specific needs of the particular electrical device. This transformation is critical in ensuring that the electrical supply is consistent, adequate, and safe for the devices it powers.One of the leading manufacturers of voltage transformers in the market is the company. Combining innovative technology and quality materials, the company has been producing voltage transformers that meet the highest standards of electrical safety and efficiency.With over 30 years of experience in the industry, the company has perfected their craft in designing and producing voltage transformers that cater to different electrical applications. Their products range from low and medium voltage transformers (need specific voltage range) to special voltage transformers used in critical systems like hospitals, airports, and data centers.The company's quality control process is second to none. Each transformer they produce goes through rigorous testing and inspection stages to ensure that it meets regulatory standards. This process guarantees that their products are free from defects and will perform exceptionally well in any setting.The company's focus on sustainability is also a vital aspect of their operations. They aim to reduce their carbon footprint and minimize waste by using environmentally friendly materials in their production process. By doing so, they've gained a reputation for being one of the most eco-friendly manufacturers in the industry.One of the company's latest products is the (need to describe the product). This product is designed to meet the growing demand for voltage transformers with higher efficiencies and improved performance in renewable energy applications. The transformer's design allows for seamless integration into renewable energy sources like solar power and wind turbines. With this product, the company is leading the way in providing environmentally friendly solutions for the energy industry.The (need to remove brand name) transformer is built to last and has a longer lifespan compared to other transformers on the market. It's also user-friendly, with easy installation and maintenance procedures that reduce downtime and repair costs.The transformer comes with advanced features that make it stand out from its competitors. It has an intelligent monitoring system that constantly monitors the transformer's performance and can detect any issues that may arise. This feature ensures that users are notified of any potential problems before they become severe, preventing costly damages and repairs.The transformer's design is also compact and lightweight, making it easy to transport and install in any location. It has been tested in harsh weather conditions and has proven to be highly durable in extreme temperatures without compromising on performance.In conclusion, the demand for electricity is not slowing down anytime soon, and as such, the need for voltage transformers that are efficient, safe, and eco-friendly is crucial. The (need to remove brand name) transformer from the company has proven to be a gamechanger in this regard. It's a testament to the company's commitment to sustainable development and innovation in the energy industry. With several unique features that set it apart from its competitors, the (need to remove brand name) transformer is undoubtedly a top choice for anyone in need of a high-quality voltage transformer.

Insulated Load Break Elbow Connector for Underground Cable Connections

- Underground Cable - Distribution Power System - Pad-Mount Transformer - Insulated Plugin Termination - Fully-Shielded - Surrounding Power Supply Branch Box - Cable Branch Box - Loadbreak Elbow ConnectorUnderground power distribution systems play a vital role in our daily lives as they deliver the electricity we need to power our homes, businesses and communities. A distribution power system comprises of various components and one such component that is crucial for efficient and secure power delivery is the Loadbreak Elbow Connector.The Loadbreak Elbow Connector is a fully-shielded, insulated plugin termination that is used to connect underground cable to the distribution power system of pad-mount transformers, surrounding power supply branch boxes, and cable branch boxes equipped with load break switches. This essential component enables efficient and secure power distribution by providing a reliable and secure connection between cables and transformers.What is a Loadbreak Elbow Connector?A Loadbreak Elbow Connector is an essential component of the underground power distribution system that enables the connection of underground cables to pad-mount transformers, power supply branch boxes, and cable branch boxes equipped with load break switches. A Loadbreak Elbow Connector is a fully-shielded and insulated plugin termination that ensures secure and reliable power distribution.Features of a Loadbreak Elbow ConnectorLoadbreak Elbow Connectors are designed to provide reliable and secure connections between underground cables and transformers or branch boxes. Some of the key features of a Loadbreak Elbow Connector include the following:Fully shielded - Loadbreak Elbow Connectors are fully shielded to protect against electromagnetic interference and ensure reliable transmission of power.Insulated - Loadbreak Elbow Connectors are insulated to prevent accidental contact with live conductors and ensure the safety of personnel.Easy to install - Loadbreak Elbow Connectors are easy to install and require minimal maintenance.High current rating - A typical Loadbreak Elbow Connector has a current rating of 200A, making it suitable for high current applications.Benefits of a Loadbreak Elbow ConnectorReliable power distribution - Loadbreak Elbow Connectors provide a reliable and secure connection between underground cables and transformers or branch boxes, ensuring efficient and safe power distribution.Easy to install - Loadbreak Elbow Connectors are easy to install and require minimal maintenance, ensuring smooth and hassle-free operations.Enhanced safety - Loadbreak Elbow Connectors are fully insulated, preventing accidental contact with live conductors and enhancing the safety of personnel.Cost-effective - Loadbreak Elbow Connectors are cost-effective as they are designed to provide long-lasting, dependable service.ConclusionIn conclusion, a Loadbreak Elbow Connector is a crucial component of the underground power distribution system that ensures reliable and secure power distribution. Its features and benefits make it an essential component for efficient and safe delivery of electricity. With its fully-shielded and insulated design, the Loadbreak Elbow Connector provides a reliable and safe connection between underground cables and transformers or branch boxes, ensuring efficient and safe power distribution. So, if you are looking for a reliable and cost-effective solution to your power distribution needs, then the Loadbreak Elbow Connector is the way to go.

How to Install 200A Loadbreak Elbows for Cable Accessories

If you want to seamlessly connect a 15kv/24kv 200a cable to a power system, you need the right cable accessories. One of the most important accessories for this kind of application is a loadbreak elbow. In this blog post, we'll take a closer look at what loadbreak elbows are and how to install them properly.Loadbreak elbows are designed to provide a safe and easy way to connect underground power cables to transformers, switchgear, and other equipment. They are most commonly used in medium-voltage applications, such as distribution networks and industrial installations.When selecting a loadbreak elbow, it's important to choose one that's rated for the voltage and amperage of your application. For a 15kv/24kv 200a cable, you'll need a loadbreak elbow rated for at least 15kv and 200a.Once you've selected the right loadbreak elbow, installation is relatively straightforward. Here's a step-by-step guide to installing a 200A loadbreak elbow:Step 1: Prepare the cableFirst, you'll need to prepare the cable by stripping back the insulation to expose the conductor. Make sure the conductor is clean and free of any dirt or debris.Step 2: Install the elbow onto the cableNext, slide the loadbreak elbow onto the end of the cable. Make sure the elbow is fully seated and there is no exposed conductor.Step 3: Crimp the elbowUse a crimping tool to crimp the loadbreak elbow to the cable. Make sure the crimp is tight and secure.Step 4: Install the connector onto the equipmentSlide the other end of the loadbreak elbow into the connector on the equipment. Make sure the connector is fully seated and there is no exposed conductor.Step 5: Test the installationFinally, test the installation by performing a dielectric test to ensure there are no leaks or other faults. A dielectric test involves applying a high voltage to the cable and checking for any current leakage.By following these steps, you can install a 200A loadbreak elbow for your 15kv/24kv cable with ease. It's important to note that if you're not confident in your ability to install the elbow yourself, you should consult a qualified electrician or technician.In conclusion, loadbreak elbows are an essential cable accessory for connecting underground power cables to equipment in medium-voltage applications. Make sure you choose the right loadbreak elbow for your application, and follow the proper installation procedures to ensure a safe and reliable connection.

New Cable Connector Allows for Simplified Rear Wiring in Vehicles

article:Innovation is at the heart of most businesses' success. In today's world, success is measured not only by how much a company can make in profits but also by how much it can contribute to the technology industry. Many businesses try to come up with breakthrough technologies that will change how we do things and bring new solutions to old problems. One such breakthrough technology that has been making waves in the industry lately is the Rear Tee Cable Connector. This invention has revolutionized the cable connection industry and is one of the most innovative creations of its time.The Rear Tee Cable Connector is a piece of technology that has been designed to improve the way cables are connected. In the past, cable connections have been known to be problematic and most users have had to deal with various issues when it comes to cable connectivity. However, the Rear Tee Cable Connector, which is usually connected to an electrical cable, has come to eliminate these issues. With this technology, the cable is connected faster, more securely, and at a lower cost.The Rear Tee Cable Connector has been designed by a leading electrical company that has been at the forefront of electrical technology for many years. This company has a reputation for creating innovative and high-quality technologies that have helped revolutionize how we live, work and play. The industry leader has always strived to deliver the best solutions to its clients and the Rear Tee Cable Connector is no exception.The company's president gave a brief statement about the Rear Tee Cable Connector saying, "We are dedicated to creating technology that enables our clients to work smarter, not harder. We are excited to introduce the Rear Tee Cable Connector, which is a significant breakthrough in the cable connection industry. This technology eliminates problems associated with cable connections, improves connectivity, increases speed, and greatly reduces costs. We are excited to have played a significant role in bringing this technology to the market."The Rear Tee Cable Connector is made from high-quality materials and is designed to meet the rigorous needs of the electrical industry. It has been tested and shown to surpass industry standards in terms of quality, strength, and durability. The Connector is easy to install, which is a departure from traditional connectors that can be complicated.The Rear Tee Cable Connector has many features that set it apart from other cable connectors. One of its most notable features is its design which ensures that the cable is fully secured. The connector has a locking mechanism that holds the cable firmly in place, ensuring that it does not come loose. In addition, the Connector has a waterproofing feature that makes it ideal for use in harsh environments. This means that the Connector can withstand exposure to water, chemicals, and other elements that can damage conventional connectors. The Rear Tee Cable Connector also reduces downtime which is a significant issue in the electrical industry. This is accomplished by reducing the amount of time required to install it. Unlike traditional connectors that can be time-consuming and challenging to install, the Rear Tee Cable Connector has a more straightforward installation process which saves time and helps to minimize downtime. This is a significant advantage for companies that rely on continuity to keep their operations running smoothly.In conclusion, businesses and organizations that need efficient, secure and cost-effective electrical cable connectors can now use the Rear Tee Cable Connector with the assurance that they are using a breakthrough technology that delivers results. The Connector's design, strength, and durability set it apart from conventional connectors, and it is quickly becoming the preferred choice for many businesses. As the world moves towards a future that depends heavily on technology, innovations like the Rear Tee Cable Connector will continue to be a game-changer for many industries.

High-Quality Single Phase Potential Transformers with Built-In Fuse for Accurate Electricity Measurement

20kv Single Phase Potential Transformer With Fuse Factory Expands ProductionThe demand for electricity has been increasing rapidly, and with it, the demand for quality electrical equipment has also been on the rise. In response to this, {Company} has expanded its production of 20kv Single Phase Potential Transformer With Fuse, which is a vital component in electricity distribution systems.The 20kv Single Phase Potential Transformer With Fuse is widely used in electrical distribution systems to convert high voltage electricity to low voltage electricity. The transformer works by stepping down the voltage level, making it safe for use in homes, offices and other commercial buildings.As the handling of electricity is complex and dangerous, it is essential to have a transformer that is safe, reliable and efficient. With the increased demand for electricity, the demand for these transformers is also on the rise.{Company} has been in the business of manufacturing 20kv Single Phase Potential Transformer With Fuse for many years. Over the years, their reputation has grown, and they have become a trusted supplier of quality electrical equipment. With the expansion of their production, they aim to meet the growing demand for this transformer.According to the management of {Company}, the new production line will allow them to produce 20kv Single Phase Potential Transformer With Fuse more efficiently and in larger quantities. This, in turn, will help them to fulfil orders from both local and international customers.The expansion of the production line is expected to provide a boost to the local economy, as it will create job opportunities for skilled workers, engineers and other professionals. This will help to reduce unemployment levels and create new opportunities for people in the area.As part of their commitment to quality, {Company} has implemented strict quality control measures to ensure that their transformers meet international standards. They have also invested in modern technology to improve their production process and make it more efficient.The company has also put measures in place to ensure that their transformers are environmentally friendly. As the demand for electricity continues to grow, it is essential that the equipment used in the industry is energy efficient and sustainable. {Company} has made this a priority, and their transformers have been designed to reduce energy consumption and minimise the impact on the environment.{Company} has a dedicated team of experts who work tirelessly to ensure that their transformers meet the needs of their customers. They are committed to providing excellent customer service and support, and they work closely with their clients to understand their needs and deliver solutions that are tailored to their requirements.In conclusion, the expansion of {Company}'s production line for 20kv Single Phase Potential Transformer With Fuse is a significant development in the electrical industry. With their commitment to quality, efficiency and sustainability, they are well-positioned to meet the growing demand for this transformer.Their investment in modern technology, strict quality control measures and environmental sustainability demonstrates their commitment to providing innovative solutions that meet the needs of their customers. As the demand for electricity continues to rise, {Company} is poised to play a vital role in providing the equipment needed to power the world.

Cold Shrink Sleeving for Easy Waterproofing and Insulation of Cable Joints and Connectors

For Waterproofing, Insulation, Cable Joints, Coax Connector Sealing Kit, Telsto, and Cold Shrink Splice Cover Kits.Cold Shrink Sleeving For Waterproofing and Insulation, Cable Joints /Coax Connector Sealing Kit - Telsto DescriptionAs industries continue to advance, the need for reliable and durable insulation and waterproofing solutions keeps increasing. In the telecommunication industry, the use of cables and connectors is crucial, and it is important to ensure that they are safely insulated and waterproofed to avoid damage and ensure longevity. Telsto, a company specializing in telecommunication products, has introduced the Cold Shrink Splice Cover Kits, an innovative solution designed to provide easy and safe installation of waterproof and insulated splices on spacer cable.The Telsto Cold Shrink Splice Cover Kits are designed with open-ended rubber sleeves that are pre-expanded in the factory and assembled onto removable plastic cores. The pre-expanded nature of the rubber tubes ensures easy and fast installation, which saves time and resources compared to other traditional insulation solutions. Additionally, the rubber material used in the construction of the tubes is safe for the environment, making the Cold Shrink Splice Cover Kits an eco-friendly solution.The Cold Shrink Splice Cover Kits come in different sizes, depending on the splice diameter and the spacer cable's thickness. The rubber tubes are compatible with different types of cable jackets and are designed to provide excellent protection against moisture, UV rays, and other environmental factors that can damage the cable splices. One of the key advantages of the Telsto Cold Shrink Splice Cover Kits is the ease of installation. The removable plastic core ensures that the tube remains in place during installation, providing a tight and secure seal that protects the splice from damage and allows for proper themal insulation. Once the tube is in place, the plastic core is removed, and the rubber tube shrinks to create a tight and secure seal. The simplicity of this installation method makes it possible for anyone, regardless of their experience, to install the Cold Shrink Splice Cover Kits effectively.In addition to the Cold Shrink Splice Cover Kits, Telsto also offers Coax Connector Sealing Kits, which are designed to provide a waterproof solution for outdoor coaxial connectors. The kits come with silicone rubber seals and caps that are easy to install and provide excellent protection against moisture and dust. Coax Connector Sealing Kits are available in different sizes and can be customized to fit specific requirements.In conclusion, Telsto's Cold Shrink Splice Cover Kits and Coax Connector Sealing Kits provide reliable and durable solutions for telecommunication insulation and waterproofing needs. The kits are easy to install, safe, and environmentally friendly, making them ideal for various industrial applications. The Cold Shrink Sleeving For Waterproofing and Insulation, Cable Joints /Coax Connector Sealing Kit - Telsto, is a testament to the company's commitment to providing innovative products that meet the ever-increasing demands of the telecommunication industry.

Effective Transformer Protection with High Voltage Current-Limiting Fuse

When it comes to protecting transformers, one of the most important components to consider is the fuse. High voltage fuses are incredibly important because they help prevent current overloads, which can ultimately lead to catastrophic damage or even complete destruction of the transformer.China High Voltage Fuse for Transformer ProtectionChina is known for producing high-quality components for power systems, including transformers. One of the key components that they manufacture is high voltage fuses for transformer protection. These fuses act as a safety mechanism, preventing excess current from flowing through the transformer and causing damage.The Wenzhou Shuguang Fuse Co., Ltd. is a leading manufacturer of high voltage fuses in China. Their products are known for their high quality, durability, and reliability. They offer a range of fuses for transformers of all sizes and voltages, ensuring that the right product is available for every application.Fuse for Transformer ProtectionTo protect transformers from excess current, a fuse is needed. The fuse acts as a safety valve, breaking the circuit if the current reaches a certain level. This prevents further current flow, protecting the transformer from damage. Without a fuse, the transformer would be at risk of overheating, which could cause permanent damage or even a fire.Current-Limiting FuseOne type of high voltage fuse commonly used for transformer protection is the current-limiting fuse. This type of fuse operates by limiting the current flow without completely breaking the circuit. This helps to protect the transformer components while keeping the system operational. Current-limiting fuses are often used in high-power applications, such as industrial or commercial transformers.10kv Potential Transformer With Fuse Protection Made In ChinaChina is a major manufacturer of high voltage components, including fuses for transformer protection. One of the most common types of transformers used in China is the 10kv potential transformer. These transformers are used in a variety of applications, from power plant distribution to industrial automation.To protect these transformers, a fuse is necessary. High-quality, reliable fuses can be found in China, including those manufactured by the Wenzhou Shuguang Fuse Co., Ltd. Their products are designed to withstand high voltages and current loads, ensuring that transformers are protected from damage.ConclusionHigh voltage fuses are a crucial component in any transformer protection system. In China, the Wenzhou Shuguang Fuse Co., Ltd. is a leading manufacturer of high-quality fuses for transformer protection. Their current-limiting fuses are designed to protect transformers of all sizes and voltages, including the 10kv potential transformer. By using reliable fuses, transformers can be protected from damage, ensuring that power systems operate safely and efficiently.

Enhance Your Cable Connections with the Latest Front Tee Connector

[News Headline]Front Tee Cable Connector: Revolutionizing Connectivity Solutions for the Modern World[News Introduction]In an era where seamless connectivity is paramount, companies across industries are constantly striving to develop innovative solutions that enhance productivity, efficiency, and reliability. Enter Front Tee Cable Connector, a groundbreaking technology that promises to revolutionize connectivity solutions for the modern world. With its unrivaled performance, user-friendly design, and commitment to quality, this cutting-edge device is set to reshape the way we connect and communicate.[Company Introduction]Front Tee Cable Connector, a leading technology company, has established itself as a pioneer in the field of connectivity solutions. With years of research and development, the company has consistently pushed the boundaries of what is possible in the realm of cable connectors. By combining state-of-the-art technology with meticulous engineering, Front Tee Cable Connector has earned a reputation for delivering products that exceed expectations.Headquartered in [location], Front Tee Cable Connector is dedicated to meeting the ever-evolving demands of its customers. With a global presence spanning multiple continents, the company has established itself as a trusted partner for businesses of all sizes. Front Tee Cable Connector's commitment to innovation, reliability, and customer satisfaction has made it an industry leader and a key player in the connectivity solutions market.[News Content]1. Unrivaled Performance and Connectivity:Front Tee Cable Connector boasts unparalleled performance that sets it apart from its competitors. Designed to optimize signal quality and minimize data loss, this connector ensures a stable and reliable connection, even in the most demanding environments. With its high bandwidth capabilities, it is perfectly suited for applications that require fast and uninterrupted data transfer, such as telecommunications, data centers, and industrial automation.The advanced technology employed in Front Tee Cable Connector allows for superior signal integrity, resulting in reduced latency and improved overall network performance. This exceptional performance makes it an ideal solution for industries that rely on real-time data processing and transmission.2. User-Friendly Design:Ease of use and installation are key features of Front Tee Cable Connector. The ergonomic design and intuitive interface make it a breeze to connect and disconnect cables, saving time and effort. With its foolproof plug-and-play functionality, even non-technical users can effortlessly set up and maintain connections.Additionally, Front Tee Cable Connector's compact and space-saving design makes it ideal for cramped or densely packed environments. Its versatility allows it to seamlessly integrate into various setups, ensuring maximum compatibility and flexibility.3. Commitment to Quality and Reliability:Front Tee Cable Connector prioritizes quality and reliability above all else. With rigorous testing and quality control procedures in place, every connector that leaves their facilities meets the highest industry standards. The company's dedication to excellence is evident in its products, which undergo extensive performance testing to ensure long-term durability and usability.Furthermore, Front Tee Cable Connector's customer-centric approach guarantees exceptional support and assistance throughout the entire customer journey. Their team of experts is always on hand to provide technical guidance, answer queries, and address any concerns - ensuring a smooth experience from purchase to installation.4. Contributing to a Sustainable Future:Front Tee Cable Connector understands the importance of sustainability in today's world. The company actively invests in research and development to create environmentally friendly products that reduce energy consumption and minimize environmental impact. By utilizing eco-friendly materials and optimizing manufacturing processes, Front Tee Cable Connector is committed to a greener, more sustainable tomorrow.[Conclusion]Front Tee Cable Connector's revolutionary technology is transforming the connectivity landscape, offering unparalleled performance, user-friendly design, and a commitment to quality. With businesses and individuals increasingly reliant on seamless connectivity, Front Tee Cable Connector emerges as a trusted partner for all connectivity needs. As the world continues to evolve and demand faster, more reliable connections, this innovative solution promises to deliver on all fronts.

Discover a Wide Range of Fibre Optic Tools and Termination Kits for Your Needs

, Fibre Optic Tools, Anderson Corporation, Fibre Optic Technology, Fibre Optic Cable, Optical Network.Fibre optic technology has revolutionized the way we communicate and transfer data today. With its high-speed capabilities, low latency, and reliable signal strength, fibre optic cables are the preferred choice for telecommunications networks, data centres, and other high-bandwidth applications. However, to design, install, and maintain fibre optic cable networks, one needs specialized tools and equipment. In this blog, we will explore the various types of fibre optic tools and termination kits available at Anderson Corporation.Fibre Optic ToolsFibre optic tools are specialized equipment designed to handle fibre optic cables and the installation process. Tools such as cable strippers, cleavers, fusion splicers, OTDR testers, and visual fault locators are some of the fibre optic tools essential for installing, maintaining and repairing fibre optic cables.A fibre optic cable stripper is used to remove the insulation layer of a fibre optic cable without damaging the thin glass fibres inside. Cable cleavers are used to precisely cut the fibre optic cable, ensuring a clean break without splinters. Fusion splicers are used to splice or join two fibre optic cables together by melting the glass fibres and fusing them together. OTDR testers or Optical Time-Domain Reflectometers are used to detect and locate faults or weak points in the fibre optic network. Visual Fault Locators are small handheld devices that emit a visible laser light to locate breaks or faults in the fibre optic network.Termination KitsFibre optic termination kits are a set of tools, connectors, and cables used to terminate or connect a fibre optic cable to a device or network. These kits are available in different types and sizes, depending on the specific project requirements.At Anderson Corporation, we offer a range of fibre optic termination kits, such as pre-polished connectors, splice-on connectors, mechanical connectors, and field-installable connectors. Pre-polished connectors are factory polished connectors that require minimal on-site polishing. Splice-on connectors are used for quick and easy termination of fibre optic cables in the field. Mechanical connectors are user-friendly, cost-effective connectors that are easy to install without polishing. Field-installable connectors are convenient and easy to install connectors used in harsh environments, remote locations, or emergency situations.ConclusionAs mentioned earlier, fibre optic technology is the future of telecommunications, and installing and maintaining fibre optic cables require specialized tools and equipment. Anderson Corporation offers a range of fibre optic tools and termination kits to ensure a smooth and successful fibre optic installation. Whether you are a network installer, contractor, or a data centre operator, we have the right tools and kits for your needs. Contact us today to learn more.

Enhanced Solar Fuse Links: Safeguarding Photovoltaic Arrays from Over-currents

for Photovoltaic Panels and Solar ArraysIn today's day and age, the use of renewable energy sources has been gaining momentum with the increasing concern for a sustainable future. As more people are turning towards solar energy, the demand for photovoltaic panels has also been on the rise. Photovoltaic panels are essentially an assembly of solar cells that convert sunlight into usable energy. However, these panels are vulnerable to various faults and over-currents, which can pose a serious threat to the overall health of the system. That's where the protection fuse link for photovoltaic panels and solar arrays comes into play.The range of 1038mm fuse links is specifically designed for the protection of photovoltaic (solar panel) strings. These fuse links are capable of interrupting low over-currents associated with faulted photovoltaic string arrays. The ability to detect and isolate faults quickly ensures that the overall system remains safe and free from any damage.Rated for a voltage of 1000V DC and a current ranging from 1A to 32A, these fuse links are essential in preventing any damage to the solar panel array. The fuse links work as a barrier between the system and any over-currents by detecting and interrupting the flow of electricity when there is a fault. This ultimately ensures the safety of the system and prevents any potential damage.Photovoltaic panels are known to be a costly investment, and any damage or downtime can have a considerable impact. Therefore, the use of protection fuse links is crucial in ensuring the longevity and optimal performance of the system. In case of any fault or over-current, the fuse link will break the circuit, thereby preventing the fault from spreading throughout the system and causing more significant damage.The protection fuse link for photovoltaic panels and solar arrays is an important component for the overall safety and protection of the system. With the increasing demand for renewable energy, the use of photovoltaic panels is only set to rise, and the installation of the protection fuse link is crucial in ensuring the safety and optimal performance of the system.In conclusion, the protection fuse link is an essential component for the safety and protection of photovoltaic panels and solar arrays. The ability to detect and isolate faults quickly ensures that the overall system remains safe and free from any damage. As the demand for renewable energy sources continues to rise, the use of photovoltaic panels will become even more prevalent, making the installation of the protection fuse link even more crucial. So, whether you are looking to invest in a solar panel system for your home or office, make sure to consider the importance of the protection fuse link for optimal performance and longevity of the system.